Progress from M13 to M24

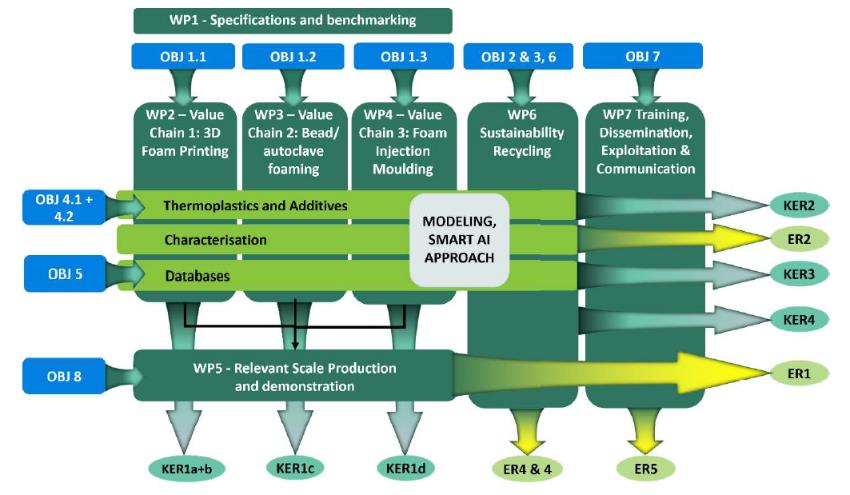

The VITAL project focuses on developing foaming processes for bio-based thermoplastic (b-bTP) materials. In order for foamed thermoplastic processing value chains to transition to sustainable, circular bio-based solutions, critical limitations must be overcome. This project will not only contribute to a circular and sustainable economy but will also deliver cleaner, more climate-neutral industrial processes. The work programme for the VITAL project is shown to the right. We have now entered the final year of this 3-year project, and this Newsletter highlights achievements from the past 12 months.

Site visits and General Assembly meetings

VITAL held its 4th General Assembly on 16th January online, followed by the Period 1 Review meeting 1 week later in Brussels, Belgium, on 24th January. During these two meetings, the consortium gathered to review the progress made and plan the activities for the next period, with the assistance of the Project Officer and external expert. The Review provided a good opportunity to reflect on the successes to date while identifying areas of focus and improvement for the final project period.

The 5th General Assembly meeting was held between 11th and 12th June 2024 at partner PIEP’s site in Guimaraes, Portugal, where the progress of the project was reviewed, and plans were made for the following year. Several workshops were held, focusing on demonstration use cases and development of training courses and a site tour and networking event was held at PIEP’s Centre for Innovation in Polymer Engineering, which is home to an impressive processing hall, workrooms, project demonstrator facilities and test labs.

Updates on the technical work packages

Despite some delays due to the level of technical challenge associated with aspects of the foaming work, the consortium has delivered promising results, which will help us optimize the processes for producing the case study parts.

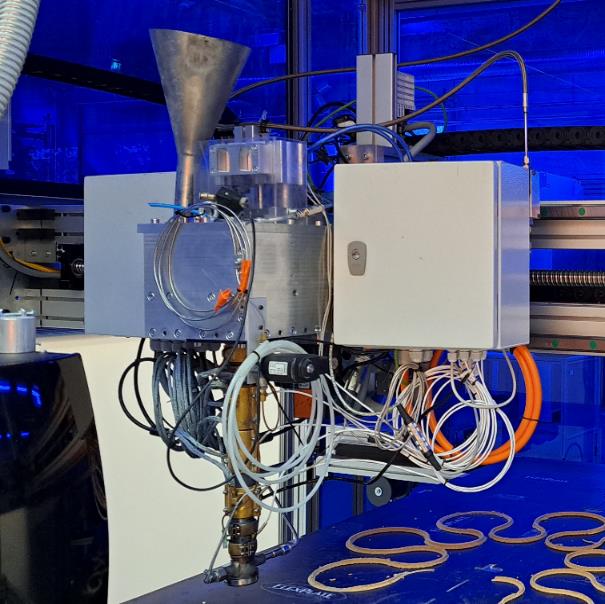

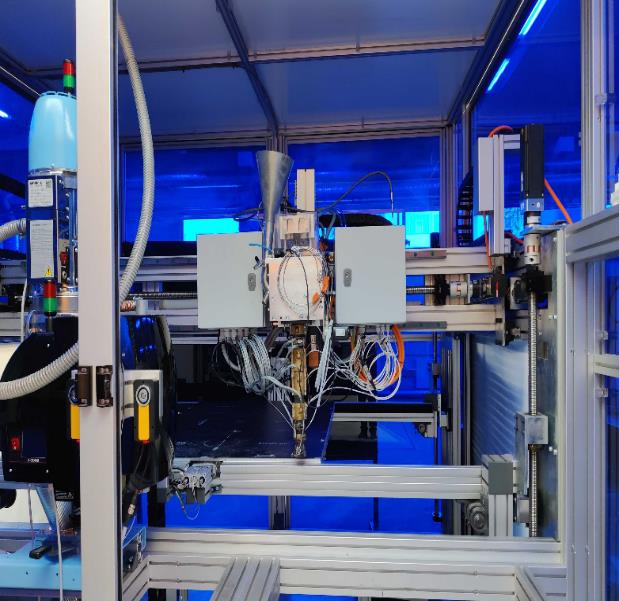

Work Package 2. Value Chain 1: 3D Foam Printing

The 3D printing platform has now been designed, built and trialled at VTT with support from Brinter. To date, samples have been produced with commercial PS and FLOREON’s Duratech PLA. The printer head has been shipped to BRINTER for integration into their 3D printing platform to produce the demonstrator parts. An online rheometer head has been successfully tested and used to study high-pressure rheology for polymer foams. The data from this study is being used to calibrate two computer models: a 3D foam extrusion nozzle model using CFD and an in-house extrusion model for simulating the nozzle and heater/cooler parts of the extruder.

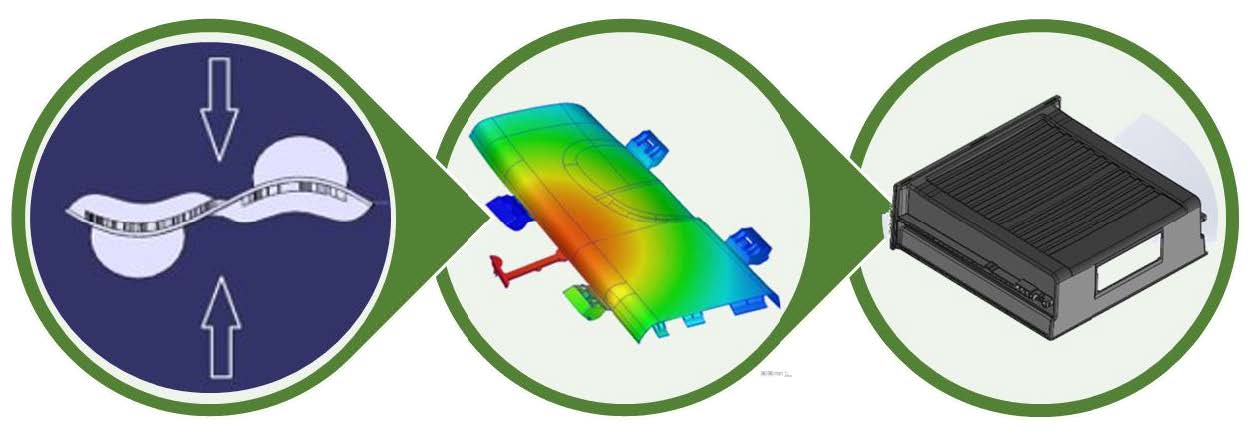

Work Package 3. Value Chain 2: Bead Foaming and bead foam processing

A range of b-bTPs and additive formulations have been selected based on trials to optimise foam process and bead foam moulding process parameters, as well as foam fusing behaviour. New biobased polyamides have been developed, with process optimisation and scale up currently in progress. An autoclave process has been developed to produce PLA foam beads. Test samples have been produced from these using RF moulding processes and production of case study parts has now started.

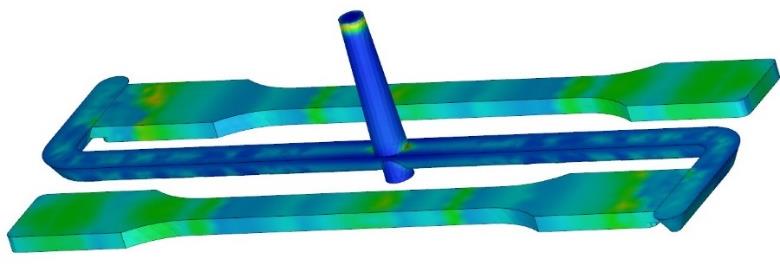

Work Package 4. Value Chain 3: Injection moulding and foam moulding

Adaptations were made to the Foam Injection Moulding (FIM) equipment to ensure the proper fitting of the injection unit. Using this modified FIM, materials have InnoVatIve processing Technologies for bio-based foAmed thermopLastics been produced using b-bTPs and 3 different chemical foaming agents (CFA). It was noted that foams of variable density were created when different CFA was used. All 3 materials were then subject to preliminary material testing, confirming compliance with ISO requirements. Testing to ensure the materials meet the requirements established by the end users is currently ongoing. Work is also underway to create a virtual AI model that will enable control of all the parameters in the printer head. This model will support prediction of the quality of the b-bTPs formed based on the inputs from FIM.

Work Package 5. Demonstration of use cases

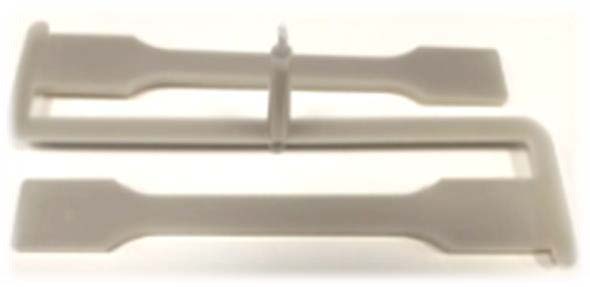

The bio-based thermoplastics produced are being used as substitutes for non-recyclable material in electronics/white goods, automative and in marine components. For each component, evaluation and definition of requirements for future use has been completed. Test samples are currently being evaluated against specifications. Design of the component and moulds and simulation studies are underway with production of case study components due to start soon.

Work Package 6. Sustainability

An open access database is being created based on VITAL’s biobased thermoplastic testing and

characterisation data. This database will help stakeholders identify the best materials and processing conditions to meet diverse needs. Recyclability, refurbishment and remanufacturing processes are being evaluated at PIEP. FLOREON’s PLA formulations have been studied through reprocessing cycles by MFR, rheological performance and calorimetric analysis to evaluate end-of-life behavior. Conventional process baseline data for LCA and TEA has been collated and assessed by IDENER, with comprehensive LCA and TEA studies for VITAL processes and materials to be completed towards the end of the project.

Dissemination & Communication

VITAL project has presented at a number of meetings during this period including:

✓ Polymers 2024 – Polymers for a Safe and Sustainable Future conference (Athens, Greece)

✓ Plastics Live 2024 (Coventry, UK)

✓ EUBCE (Marseille, France)

✓ 5th International Congress on Advanced Materials Sciences and Engineering (Opatija, Croatia).

BIOMATTERS cluster

The BIOMATTERS cluster have now been working together for over 1 year. The cluster was formed by the projects funded under the call the HORIZON-CL4-2021- TWIN-TRANSITION-01-05 “Manufacturing technologies for bio-based materials”. To date activities have included workshops on LCA methodology and stakeholder mapping, joint social media campaigns, Horizon Europe Booster application and brand development, a side event at EUBCE 2024, and presentations at S3 Congress.

Further activities are now being planned with a likely return to EUBCE in 2025 and an afternoon of presentations and case study demonstrations at the WASTE2BIOCOMP final event in Brussels May 2025.

AMBIANCE – BIO-UPTAKE – GREEN-LOOP – NEWWAVE – WASTE2BIOCOMP – VITAL

Upcoming Events

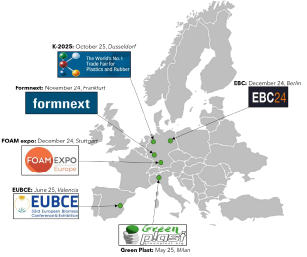

In the next period, members of the VITAL consortium will attend and present at the following events. We hope

to see you there!

Contact Us

Contact Us

Lisa Wikström

VITAL Project Coordinator

VTT Technical Research Centre of Finland Ltd

Sustainable product and materials

lisa.wikstrom@vtt.fi

Website: https://vital-project.eu/

Linkedin: www.linkedin.com/in/hevitalproject

Twitter/X: https://twitter.com/VITALHEProject

Email: vitalhorizoneurope@gmail.com